The Role of a Quality Ford Fiesta Engine in Vehicle Performance

The Role of a Quality Ford Fiesta Engine in Vehicle Performance

Blog Article

Opening the Power of Engines: A Comprehensive Guide to Efficiency and Efficiency

Comprehending the elaborate technicians of engines is essential for both efficiency enthusiasts and day-to-day drivers. The responses might redefine our strategy to engine efficiency and efficiency in methods that are both informing and crucial.

Understanding Engine Fundamentals

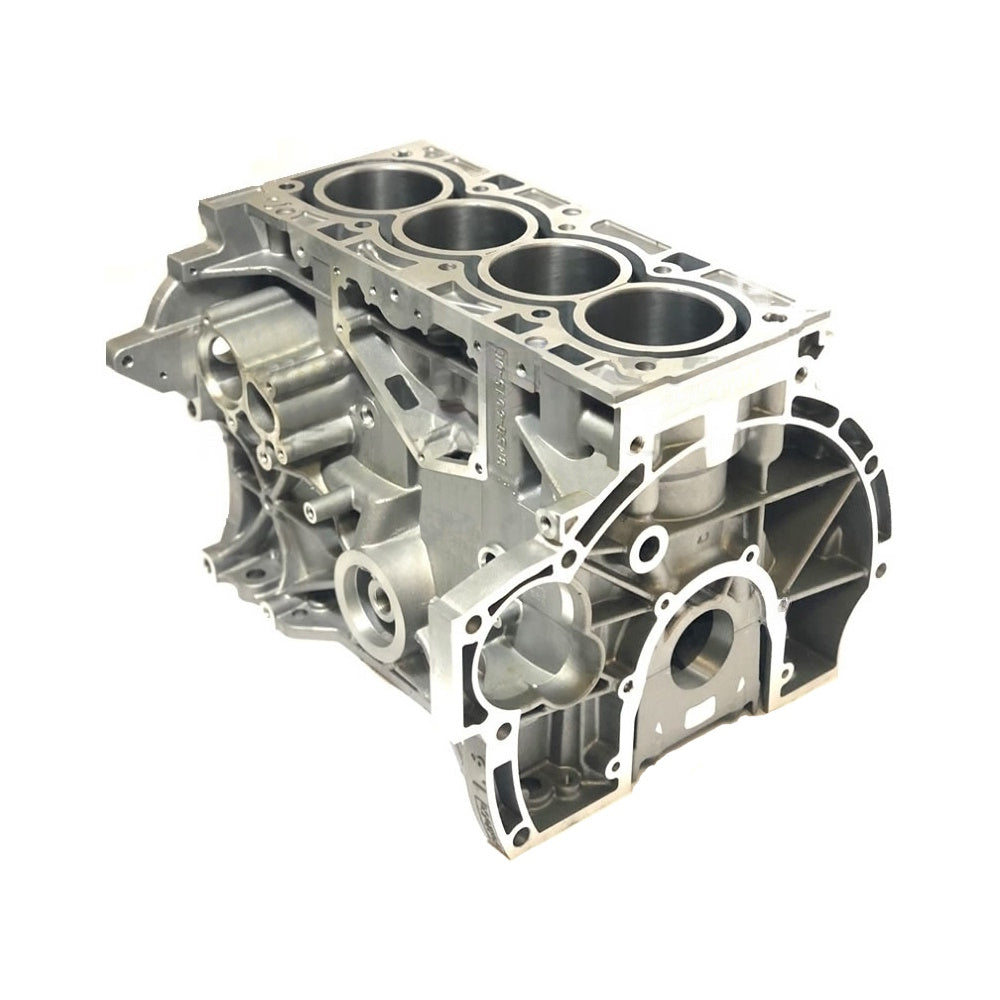

What makes up the essential technicians of an engine? At its core, an engine is a machine designed to transform gas right into mechanical power via a collection of regulated explosions or combustion procedures. The key elements consist of the cyndrical tube, piston, crankshaft, camshaft, and shutoffs. The cylinder serves as the chamber where burning occurs, while the piston moves within the cylinder to convert the power from burning right into straight activity (ford fiesta engine).

The crankshaft then changes this straight motion right into rotational power, which eventually powers the car. The camshaft controls the opening and closing of the shutoffs, regulating the intake of air and gas and the expulsion of exhaust gases. Furthermore, the engine relies upon a very carefully calibrated fuel-air combination, ignition system, and cooling system to ensure ideal performance and effectiveness.

Understanding engine essentials likewise entails acknowledging the significance of engine cycles, such as the four-stroke cycle, which consists of intake, exhaust, power, and compression strokes. Each stage is crucial in making certain the engine functions efficiently and effectively. Proficiency of these essential technicians prepares for exploring a lot more complex engine dynamics and efficiency metrics, essential for enhancing both power output and performance.

Key Efficiency Metrics

Trick performance metrics are crucial for examining an engine's effectiveness and power output, providing beneficial understandings for both suppliers and consumers. These metrics act as benchmarks for engine performance, enabling for educated decisions in acquiring, layout, and production.

Among the primary metrics is horsepower, which evaluates the engine's ability to do job over time. Torque, determined in pound-feet, is an additional important statistics that shows the engine's rotational force, straight impacting velocity and pulling ability. Gas efficiency, typically determined in miles per gallon (MPG) or liters per 100 kilometers (L/100km), evaluates exactly how successfully the engine converts fuel into activity, influencing functional expenses and ecological considerations.

In addition, thermal performance procedures exactly how well an engine converts fuel energy into useful job, disclosing understandings right into power losses largely via heat. Emission levels, consisting of carbon dioxide and NOx, are additionally crucial, showing the engine's ecological effect and conformity with regulative criteria.

Tuning Techniques for Effectiveness

Tuning methods play a substantial duty in enhancing engine efficiency by enhancing efficiency metrics recognized in earlier discussions (ford fiesta engine). Various techniques exist to adjust an engine, each contributing to enhanced gas economy and decreased discharges

One efficient strategy is readjusting the air-fuel ratio, making sure the engine runs within the ideal combustion program. A leaner combination can enhance fuel effectiveness, yet it has to be balanced to avoid misfires or engine knock. Furthermore, reprogramming the engine monitoring system can rectify parameters such as ignition timing, which even more boosts efficiency while maintaining power outcome.

One more important approach involves customizing the consumption and exhaust systems. Updating to high-performance air filters and exhaust headers can minimize back pressure, facilitating better air movement. This enables the engine to breathe more openly, leading to boosted combustion efficiency.

In addition, the application of advanced adjusting devices, like dyno testing, provides specific information that enables targeted adjustments. Consistently keeping track of these efficiency metrics guarantees that tuning efforts yield the desired efficiency end results. Jointly, these strategies not just strengthen engine browse this site performance but likewise add to lasting sustainability in engine procedures.

Maintenance for Optimum Performance

Regular engine maintenance is essential for achieving optimal performance and durability. A well-maintained engine not only runs efficiently yet additionally decreases the danger of costly repairs and break downs. Key elements requiring routine focus consist of oil, filters, belts, and spark plugs.

Altering the engine oil at advised intervals is essential, as oil lubricates relocating parts and protects against getting too hot. Similarly, changing oil and air filters ensures that pollutants do not harm engine function. Disregarding these elements can bring about minimized performance and prospective engine damages.

Additionally, evaluating and changing worn belts and tubes is important to avoid unexpected failures. Timing belts, particularly, need to be changed according to the producer's schedule to stay clear of devastating engine damage.

Ignition system ought to additionally be inspected and changed as necessary, because they play an important role in ignition and fuel performance.

Future Trends in Engine Modern Technology

Embracing advancements in technology, the future of engine design is positioned to transform performance and performance across various applications. Crossbreed and completely electric powertrains are coming to be progressively mainstream, supplying minimized emissions and boosted gas effectiveness.

Moreover, advancements in materials scientific research are resulting in lighter, more powerful components that boost engine performance while lowering energy intake. Advanced manufacturing techniques, such as 3D printing, enable the development of intricate geometries that enhance air movement and thermal management, hence enhancing burning processes.

Furthermore, the integration of man-made knowledge and device learning is established to transform engine diagnostics and performance adjusting. These innovations can analyze huge amounts of data in real time, making it possible for anticipating upkeep and tailored performance improvements.

Verdict

In final thought, opening the power of engines calls for a thorough understanding of their auto mechanics and efficiency metrics. Implementing efficient adjusting techniques and click here for info adhering to normal maintenance methods significantly improve engine capacities. As the automotive landscape develops, welcoming future patterns in technology, consisting of electrification and advanced production, will be essential for maximizing performance and performance. This extensive strategy not just benefits fanatics but additionally contributes to lasting options in the realm of auto engineering.

Additionally, resource the engine counts on a carefully calibrated fuel-air mixture, ignition system, and cooling down system to guarantee optimal efficiency and performance.

Recognizing engine essentials also entails identifying the value of engine cycles, such as the four-stroke cycle, which includes intake, compression, exhaust, and power strokes. Proficiency of these essential mechanics lays the foundation for exploring a lot more complex engine characteristics and performance metrics, necessary for enhancing both power result and effectiveness.

Accepting innovations in technology, the future of engine style is positioned to transform efficiency and effectiveness throughout various applications.

Report this page